Refers to: Ship Owners / Managers/ Operators, PHRS Representatives/ Surveyors

Action Date: N/A

The American Waterways Operators (AWO) is working with the US Coast Guard to prevent and manage fatigue risks in the US tugboat, towboat and barge industry since the ‘90s. Towing vessel’ crew members are regularly exposed to the risk of fatigue, among other risks. Managing and mitigating these risks is important to reduce the likelihood of fatigue-related accidents.

With the goal of taking a proactive approach to fatigue prevention and management and reducing this risk of fatigue-related accidents, AWO’s Fatigue Risk Management Working Group developed and recently published the guide, 'Developing a Fatigue Risk Management Plan: A Guide for Towing Vessel Operators', to help member companies develop a fatigue risk management plan to incorporate into their existing safety management systems (SMS).

Fatigue risk management plans take a comprehensive, customized approach to addressing fatigue within a company, including policies and practices to address a wide range of fatigue risk factors and mitigation measures. This guide is tailored to the unique operational and environmental challenges of the towing industry. However, because towing vessel operations and design vary widely across the industry, the guide is not intended as a “one-size-fits-all” approach.

That means the companies have to carefully study the guide, assess their policies and procedures that are already in place to mitigate the fatigue-related risks of their crew members and identify how it is possible to link and possible improve their existing fatigue mitigation measures into a comprehensive fatigue risk management plan.

Companies can also use the guide to identify and implement additional practices, controls and other tools to close gaps or expand their current efforts.

The Fatigue Risk Management Working Group intends the guide to be a toolbox in which every AWO member company can find useful tools to address their specific fatigue challenges, enhancing safety of our shared waterways.

The Fatigue Risk Management Working Group has identified four core elements that it considers to be most important in a fatigue risk management plan:

- Education: Towing vessel crew members must understand the effects of poor sleep on their alertness, performance and safety, as well as know how fatigue mitigation strategies can improve sleep quality and duration.

- Environment: Various environmental factors may inhibit the ability of towing vessel crew members for quality sleep. Simple engineering solutions and behavior modifications to improve the sleep and vessel environments can improve crew members’ sleep quality.

- Work Readiness and Fatigue Reporting: Towing vessel crew members have a shared responsibility to report ready for duty, and of a company to allow adequate opportunity for crew members to rest and provide a process for reporting when they have not been able to obtain sufficient rest and/or feel fatigued.

- Performance Measurement: Companies should implement a process to regularly monitor and evaluate their fatigue management practices. This will allow them to assess whether and how these practices are being implemented, evaluate whether they are working and determine whether modifications are needed.

The Fatigue Risk Management Working Group has also identified some other elements that may affect the effectiveness of a fatigue risk management plan, such as:

- Wellness Program: companies should use wellness initiatives to educate crew members about the importance of having good sleep and it’s positive impact on health. In addition, companies must encourage healthy behaviors and provide access to physical and mental health care, as practicable.

- Commuting: Daily commuting can both impact sleep and be impacted by sleep. A fatigue risk management plan of Companies operating live-aboard vessels should evaluate the commute times and practices of crew-members, identify risks and implement feasible risk mitigation measures.

- Sustainability: Sustainability involves the integration of fatigue risk management into the safety culture of the company, and buy-in for fatigue mitigation measures from shore-side management, captains and crew members.

The guide 'Developing a Fatigue Risk Management Plan: A Guide for Towing Vessel Operators' can be found here.

Do not hesitate to contact us for any clarifications you may need on the above.

February 14th, 2019 - PHRS Head Office

Refers to: Ship Owners / Managers/ Operators, PHRS Representatives/ Surveyors

Action Date: January 1st, 2019

The Chinese Ministry of Transport and China's Maritime Safety authority (MSA) have recently (30/11/2018) took action on emissions regulations.

Specifically, an implementation plan was established by which three major

Domestic Emission Control Areas for Atmospheric Pollution from Vessels ( “DECAs”) have been designated to control and reduce emissions of atmospheric

pollutants including SOx, NOx, particulate matters (PMs) and volatile organic compounds (VOCs) from vessels and to improve the air quality of coastal areas and inland river port cities.

Among other provisions of the new requirements, from 01-01-2019, all vessels entering or operating within the DECAs should use at all times fuel with 0.5% m/m sulfur content.

The designated Domestic Emission Control Areas for Atmospheric Pollution from vessels ( DECAs) are as follows:

- Coastal control areas: all sea areas and ports within 12 nautical miles of the baseline extension of the territorial waters excluding waters under the jurisdiction of Hong Kong, Macao and Taiwan, the Hainan waters and ports.

- Inland control areas: The navigable waters of the main stream of the Yangtze River (from Shuifu, Yunnan to the mouth of the Liuhe River, Jiangsu) and the main stream of the Xijiang River (from Nanning, Guangxi to Zhaoqing, Guangdong).

More details on the exact geographic coverage of the designated DECAs and the control requirements on the SOx, NOx and PMs are shown in the implementation plan, which can be found here, published by the Chinese Ministry of Transport and China's Maritime Safety authority (MSA).

In addition, the Chinese Authorities are promoting the use of shore power for vessels at berth.

February 14th, 2019 - PHRS Head Office

Refers to: Ship Owners / Managers/ Operators, PHRS Representatives/ Surveyors

Action Date: January 1st, 2020

The Maritime Authorities of Paris MoU and Tokyo MoU on Port State Control announced that their officers will start issuing a Letter of Warning from 1st January 2019 on the sulfur content of marine fuels during inspections on ships in order to increase awareness of and to encourage timely compliance with the new requirements of MARPOL Annex VI (Regulations 14 and 18), known as the global 2020 Sulfur cap, which will enter to force from 1 January 2020.

The requirement of maximum sulfur content of 0,50% m/m for marine fuel oil will enter into force on 1 January 2020, and will have considerable implications on ship operators, the fuel oil supply chain and the industry as a whole.

For the purpose of facilitating smooth and consistent implementation of the global 2020 sulfur cap, the Paris and the Tokyo Memorandum will carry out a joint information campaign by issuing a letter of warning to ships during inspections from 1 January to 31 December 2019.

A similar approach has been already implemented by PHRS towards it's clients, ship-owners and managers by placing a relevant entry into the memoranda section of the surveys status of the applicable vessels.

Click here in order to view the relevant Press Release.

The letter of warning which may be issued by the PSCOs of Paris MoU can be found here.

February 13th, 2019 - PHRS Head Office

Refers to: Ship Owners / Managers/ Operators of Panamanian flagged vessels, PHRS Representatives/Surveyors

Action Date: January 8th, 2019

Kindly note that Merchant Marine Circular 269 issued by the Panama Maritime Authority, regarding the certification process for Maritime Labor Convention has been revised.

This revision includes the modification of paragraph 22 stating that from January 8th 2019, the ROs listed in the Circular MMC 255 may extend the validity of the Maritime Labor Certificate for a period not exceeding five months after the expiry date of the existing certificate, provided that the renewal inspection has been carried out according to standard of the MLC (A5.1.3.4). The format to be followed by the RO´s will be the same as that found in the Appendix A5–II of the Convention and will be added to the maritime labor certificate and be available to the competent authorities.

Also, paragraph 25 has been added to the circular, stating that in case of change of ship-owner or operator address, an additional inspection is not required; the RO shall re-issue administratively the full or interim maritime labor certificate with same expiry date of the previous certificate, considering that this change does not affect the operation of the ship or the Company procedures. Therefore, an authorization shall be requested to mlc@segumar.com , copy of the valid maritime labor certificate and the certificate of registry (patent) updated if applicable.

Click here for the full MMC – 269 Maritime Labor Convention 2006 (MLC 2006), Certification Process.

Do not hesitate to contact us for any clarifications you may need on the above.

February 6th, 2019 - PHRS Head Office

NL 203/18 | Maritime Cyber Risk Management

Ships are increasingly using systems that rely on digitization, digitalization, integration, and automation. Cyber technologies have become essential to the operation and management of numerous systems critical to the safety and security of shipping and protection of the marine environment.

As technology continues to develop, information technology and operational technology on board ships are being networked together and more frequently connected to the internet. Therefore the ships’ systems and networks maybe vulnerable to risks may also occur from personnel accessing systems on board, for example by introducing malware via removable media. The vulnerabilities created by accessing, interconnecting or networking these systems can lead to cyber risks which should be addressed.

Vulnerable systems could include, but are not limited to:

.1 Bridge systems;

.2 Cargo handling and management systems;

.3 Propulsion and machinery management and power control systems;

.4 Access control systems;

.5 Passenger servicing and management systems;

.6 Passenger facing public networks;

.7 Administrative and crew welfare systems; and

.8 Communication systems

To mitigate the potential safety, environmental and commercial consequences of a cyber incident, the IMO and other international shipping organizations have participated in the development of guidelines designed to assist shipping companies in formulating their own approaches to cyber risk management on board ships:

- IMO resolution MSC.1/Circ.1526 [ INTERIM GUIDELINES ON MARITIME CYBER RISK MANAGEMENT ] (which can be found here)

- IMO Resolution MSC.428 (98) [ MARITIME CYBER RISK MANAGEMENT IN SAFETY MANAGEMENT SYSTEMS ] (which can be found here)

- IMO MSC-FAL.1/Circ.3 [ GUIDELINES ON MARITIME CYBER RISK MANAGEMENT ] (which can be found here)

- ISO/IEC 27001:2013 [Information technology -- Security techniques -- Information security management systems – Requirements ]

- The Guidelines on Maritime Cyber Risk Management [Produced by BIMCO, CLIA, ICS, INTERCARGO, INTERMANAGER, INTERTANKO, IUMI, OCIMF and WORLD SHIPPING COUNCIL ] (which can be found here)

According to IMO Resolution MSC. 428 (98) on Maritime Cyber Risk Management, the objectives of the International Safety Management (ISM) Code include the provision of safe practices in ship operation and a safe working environment, the assessment of all identified risks to ships, personnel and the environment. In this scope, the Safety Management System (SMS) of the shipping companies should take into account cyber risk management in accordance with the objectives and functional requirements of the ISM Code aiming to safeguard shipping from current and emerging cyber threats and vulnerabilities. Therefore, cyber risks should be appropriately addressed in the SMS no later than the first annual verification of the company’s Document of Compliance that occurs after 1 January 2021.

For that scope, the Interim Guidelines on Maritime Cyber Risk Management [ IMO resolution MSC.1/Circ.1526 ] provides recommendations that can be incorporated into existing risk management processes. The Guidelines also include functional elements that support effective cyber risk management.

The Guidelines on Cyber Security on board Ships (please click here), reflect a deeper experience with risk assessments of operational technology, such as navigational systems and engine controls, and provides more guidance for dealing with the cyber risks to the ship arising from parties in the supply chain. For detailed guidance on cyber risk management.

Flag Administrations will soon publish their own guidelines & requirements for encouraging ship-owners and operators to take the necessary steps to safeguard shipping from current and emerging threats and vulnerabilities related to digitization, integration and automation of processes and systems in shipping. Shipping companies should carefully develop plans and procedures for cyber risk management which should be seen as complementary to existing security and safety risk management requirements contained in the International Safety Management Code (ISM) Code and the International Ship and Port Facility Security (ISPS) Code.

December 21st , 2018 - PHRS Head Office

Υπογραφή Διαπιστωτικής Πράξης από το ΥΝΑΝΠ

ΔΕΛΤΙΟ ΤΥΠΟΥ

Στις 30/01/2019, υπεγράφη η Διαπιστωτική Πράξη Συμμόρφωσης του Οργανισμού με τα κριτήρια του άρθρου 109 του νόμου 4504/2017, από το Υπουργείο Ναυτιλίας και Νησιωτικής Πολιτικής. Η υπογραφή της Διαπιστωτικής Πράξης στο σύνολο της, πιστοποιεί και την συμμόρφωση του Οργανισμού με τα κριτήρια του Κώδικα περί Αναγνωρισμένων Οργανισμών (Recognized Organizations Code) του Διεθνούς Ναυτιλιακού Οργανισμού (IMO) αναλογικά με το βαθμό εξουσιοδότησης του Οργανισμού από την Ελληνική σημαία.

Η ευτυχής αυτή κατάληξη αποτελεί ένα σημαντικό και απαιτητικό επίτευγμα για τον Οργανισμό, που δεν θα ήταν δυνατόν, χωρίς την δύσκολη και επίπονη δουλειά τόσο των στελεχών του Οργανισμού αλλά και των εντεταλμένων υπηρεσιακών παραγόντων του Κλάδου Επιθεώρησης Πλοίων (ΔΚΕΟ/ΚΕΠ) και της Διεύθυνσης Ασφάλειας Ναυσιπλοΐας (ΔΑΝ/ΥΝΝΠ) που ανέλαβαν το επίπονο έργο της διαχείρισης του διαπιστωτικού ελέγχου. Η Διαπιστωτική Πράξη Ελέγχου αντικατοπτρίζει το υψηλό επίπεδο οργάνωσης και συμμόρφωσης του Οργανισμού με τα αυστηρότερα διεθνή πρότυπα του Διεθνούς Ναυτιλιακού Οργανισμού (Ι.Μ.Ο.) στον έλεγχο της ασφάλειας και της αξιοπλοΐας των πλοίων.

Με βάση τα παραπάνω ο Οργανισμός αποκτά την δυνατότητα να διενεργεί τα παρακάτω:

• Έλεγχο και Πιστοποίηση πλοίων και ναυτιλιακών εταιρειών σύμφωνα με τον Διεθνή Κώδικα Ασφαλούς Διαχείρισης (ISM Code) και με τον ΕΚ/336/2006, καθώς και έκδοση των σχετικών εγγράφων πιστοποίησης με τα παραπάνω.

• Επιθεώρηση και Πιστοποίηση Πλοίων σύμφωνα με την Σύμβαση Ναυτικής Εργασίας – Maritime Labor Convention (MLC, 2006)

• Επιθεώρηση και Πιστοποίηση Υποστηρικτικών Πλοίων Υπεράκτιων Εγκαταστάσεων

• Επιθεώρηση και Πιστοποίηση Αλιευτικών Σκαφών άνω των 24μ. TOREMOLINOS (ΠΔ 405/1998)

Η ενεργοποίηση της διαπιστωμένης πλέον δυνατότητας του Οργανισμού να παρέχει υπηρεσίες στις παραπάνω ενότητες είναι σε εξέλιξη από τις αρμόδιες υπηρεσίες του Υ.Ν.Ν.Π. και επίκειται να ολοκληρωθεί τις επόμενες ημέρες.

At its latest Marine Environment Protection Committee (MEPC 73), IMO approved, among others, the guidance on the development of a ship implementation plan outlining how the ship may prepare in order to comply with the required sulfur content limit of 0.50% by 1 January 2020 (IMO 2020 sulfur cap) under MARPOL Annex VI.

IMO's 2020 Sulfur cap, which will take effect from 1 January 2020, requires that ships must run on fuel containing no more than 0.5% m/m of sulfur, unless having scrubbers installed.

Namely, the options available for ship-operators to achieve compliance are:

- The use of low-sulfur fuel

- Installation of scrubbers

- The use of LNG

- The use of other new developed fuels

In this context, MEPC 73 in October 2018 agreed that Administrations should encourage ships flying their flag to develop implementation plans, outlining how the ship may prepare, in order to comply with the regulation.

The plan could be complemented with a record of actions taken by the ship in order to be compliant by the applicable date.

Administrations and Port State control authorities may take into account the implementation plan when verifying compliance with the 0.50% sulfur limit requirement. A ship implementation plan is not a mandatory requirement. A lack of a ship implementation plan or an incomplete ship implementation plan should not be considered as "clear grounds" for a more detailed PSC inspection.

It is advised that ship operators schedule for each of their managed vessels a compliance plan in order to achieve compliance prior of 31st of December 2019 in respect of % content in emissions.

Under the new guidance, the ship implementation plan for 2020 could cover various items relevant for the specific ship, including, as appropriate, but not limited to:

- Risk assessment and mitigation plan (impact of new fuels)

- Fuel oil system modifications and tank cleaning (if needed)

- Fuel oil capacity and segregation capability

- Procurement of compliant fuel

- Fuel oil changeover plan (conventional residual fuel oils to 0.50% sulfur compliant fuel oil)

- Documentation and Reporting

Issues relating to use of sulfur compliant fuel oil

All fuel oil supplied to a ship shall comply with regulation 18.3 of MARPOL Annex VI and chapter II/2 of SOLAS. Meanwhile, operators could consider ordering fuel oil specified in accordance with the ISO 8217 marine fuel standard.

The following potential fuel-related issues may need to be assessed and addressed by ships in preparation for and implementation of the 0.50% sulfur limit requirement:

- Technical capability of ships to handle different types of fuel (e.g. suitability of fuel pumps to handle both higher and lower viscosity fuels, restrictions on fuels suitable for use in a ship's boilers, particularly the use of distillate fuels in large marine boilers)

- Compatibility of different types of fuels e.g. when paraffin and aromatic fuels containing asphaltenes are commingled in bunkering or fuel oil changeover

- Handling sulfur non-compliant fuels in the event of non-availability of sulfur compliant fuels

- Crew preparedness including possible training with changeover procedures during fuel switching from residual fuel oil to 0.50% compliant fuel oils.

Additionally, the ship implementation plan could be used as the appropriate tool to identify any specific safety risks related to sulfur compliant fuel oil, as may be relevant to the ship, and to develop an appropriate action plan for the organization to address and mitigate the concerns identified.

Examples should include:

- Procedures to segregate different types of fuel and fuels from different sources

- Detailed procedures for compatibility testing and segregating fuels from different sources until compatibility can be confirmed

- Procedures to changeover from one type of fuel to another or a fuel oil that is known to be incompatible with another fuel oil

- Plans to address any mechanical constraints with respect to handling specific fuels, including ensuring that minimum/maximum characteristics of fuel oil as identified in ISO 8217 can be safely handled on board the ship

- Procedures to verify machinery performance on fuel oil with characteristics with which the ship does not have prior experience.

Click here for the relevant IMO guidance MEPC.1/ Circ.878 (Guidance on the development of a ship implementation plan for the consistent implementation of the 0.50% sulfur limit under MARPOL Annex VI).

Do not hesitate to contact us for any clarifications you may need on the above.

NL 205/19 | IMO Guidance on preparing Ship Implementation Plan for 2020 Sulfur Cap Compliance

NL 205/19|IMO Guidance on preparing Ship Implementation Plan for 2020 Sulfur Cap Compliance

At its latest Marine Environment Protection Committee (MEPC 73), IMO approved, among others, the guidance on the development of a ship implementation plan outlining how the ship may prepare in order to comply with the required sulfur content limit of 0.50% by 1 January 2020 (IMO 2020 sulfur cap) under MARPOL Annex VI.

IMO's 2020 Sulfur cap, which will take effect from 1 January 2020, requires that ships must run on fuel containing no more than 0.5% m/m of sulfur, unless having scrubbers installed.

Namely, the options available for ship-operators to achieve compliance are:

- The use of low-sulfur fuel

- Installation of scrubbers

- The use of LNG

- The use of other new developed fuels

In this context, MEPC 73 in October 2018 agreed that Administrations should encourage ships flying their flag to develop implementation plans, outlining how the ship may prepare, in order to comply with the regulation.

The plan could be complemented with a record of actions taken by the ship in order to be compliant by the applicable date.

Administrations and Port State control authorities may take into account the implementation plan when verifying compliance with the 0.50% sulfur limit requirement. A ship implementation plan is not a mandatory requirement. A lack of a ship implementation plan or an incomplete ship implementation plan should not be considered as "clear grounds" for a more detailed PSC inspection.

It is advised that ship operators schedule for each of their managed vessels a compliance plan in order to achieve compliance prior of 31st of December 2019 in respect of % content in emissions.

Under the new guidance, the ship implementation plan for 2020 could cover various items relevant for the specific ship, including, as appropriate, but not limited to:

- Risk assessment and mitigation plan (impact of new fuels)

- Fuel oil system modifications and tank cleaning (if needed)

- Fuel oil capacity and segregation capability

- Procurement of compliant fuel

- Fuel oil changeover plan (conventional residual fuel oils to 0.50% sulfur compliant fuel oil)

- Documentation and Reporting

Issues relating to use of sulfur compliant fuel oil

All fuel oil supplied to a ship shall comply with regulation 18.3 of MARPOL Annex VI and chapter II/2 of SOLAS. Meanwhile, operators could consider ordering fuel oil specified in accordance with the ISO 8217 marine fuel standard.

The following potential fuel-related issues may need to be assessed and addressed by ships in preparation for and implementation of the 0.50% sulfur limit requirement:

- Technical capability of ships to handle different types of fuel (e.g. suitability of fuel pumps to handle both higher and lower viscosity fuels, restrictions on fuels suitable for use in a ship's boilers, particularly the use of distillate fuels in large marine boilers)

- Compatibility of different types of fuels e.g. when paraffin and aromatic fuels containing asphaltenes are commingled in bunkering or fuel oil changeover

- Handling sulfur non-compliant fuels in the event of non-availability of sulfur compliant fuels

- Crew preparedness including possible training with changeover procedures during fuel switching from residual fuel oil to 0.50% compliant fuel oils.

Additionally, the ship implementation plan could be used as the appropriate tool to identify any specific safety risks related to sulfur compliant fuel oil, as may be relevant to the ship, and to develop an appropriate action plan for the organization to address and mitigate the concerns identified.

Examples should include:

- Procedures to segregate different types of fuel and fuels from different sources

- Detailed procedures for compatibility testing and segregating fuels from different sources until compatibility can be confirmed

- Procedures to changeover from one type of fuel to another or a fuel oil that is known to be incompatible with another fuel oil

- Plans to address any mechanical constraints with respect to handling specific fuels, including ensuring that minimum/maximum characteristics of fuel oil as identified in ISO 8217 can be safely handled on board the ship

- Procedures to verify machinery performance on fuel oil with characteristics with which the ship does not have prior experience.

Click here for the relevant IMO guidance MEPC.1/ Circ.878 (Guidance on the development of a ship implementation plan for the consistent implementation of the 0.50% sulfur limit under MARPOL Annex VI).

February 5th, 2019 - PHRS Head Office

At its latest Marine Environment Protection Committee (MEPC 73), IMO approved, among others, the guidance on the development of a ship implementation plan outlining how the ship may prepare in order to comply with the required sulfur content limit of 0.50% by 1 January 2020 (IMO 2020 sulfur cap) under MARPOL Annex VI.

IMO's 2020 Sulfur cap, which will take effect from 1 January 2020, requires that ships must run on fuel containing no more than 0.5% m/m of sulfur, unless having scrubbers installed.

Namely, the options available for ship-operators to achieve compliance are:

- The use of low-sulfur fuel

- Installation of scrubbers

- The use of LNG

- The use of other new developed fuels

In this context, MEPC 73 in October 2018 agreed that Administrations should encourage ships flying their flag to develop implementation plans, outlining how the ship may prepare, in order to comply with the regulation.

The plan could be complemented with a record of actions taken by the ship in order to be compliant by the applicable date.

Administrations and Port State control authorities may take into account the implementation plan when verifying compliance with the 0.50% sulfur limit requirement. A ship implementation plan is not a mandatory requirement. A lack of a ship implementation plan or an incomplete ship implementation plan should not be considered as "clear grounds" for a more detailed PSC inspection.

It is advised that ship operators schedule for each of their managed vessels a compliance plan in order to achieve compliance prior of 31st of December 2019 in respect of % content in emissions.

Under the new guidance, the ship implementation plan for 2020 could cover various items relevant for the specific ship, including, as appropriate, but not limited to:

- Risk assessment and mitigation plan (impact of new fuels)

- Fuel oil system modifications and tank cleaning (if needed)

- Fuel oil capacity and segregation capability

- Procurement of compliant fuel

- Fuel oil changeover plan (conventional residual fuel oils to 0.50% sulfur compliant fuel oil)

- Documentation and Reporting

Issues relating to use of sulfur compliant fuel oil

All fuel oil supplied to a ship shall comply with regulation 18.3 of MARPOL Annex VI and chapter II/2 of SOLAS. Meanwhile, operators could consider ordering fuel oil specified in accordance with the ISO 8217 marine fuel standard.

The following potential fuel-related issues may need to be assessed and addressed by ships in preparation for and implementation of the 0.50% sulfur limit requirement:

- Technical capability of ships to handle different types of fuel (e.g. suitability of fuel pumps to handle both higher and lower viscosity fuels, restrictions on fuels suitable for use in a ship's boilers, particularly the use of distillate fuels in large marine boilers)

- Compatibility of different types of fuels e.g. when paraffin and aromatic fuels containing asphaltenes are commingled in bunkering or fuel oil changeover

- Handling sulfur non-compliant fuels in the event of non-availability of sulfur compliant fuels

- Crew preparedness including possible training with changeover procedures during fuel switching from residual fuel oil to 0.50% compliant fuel oils.

Additionally, the ship implementation plan could be used as the appropriate tool to identify any specific safety risks related to sulfur compliant fuel oil, as may be relevant to the ship, and to develop an appropriate action plan for the organization to address and mitigate the concerns identified.

Examples should include:

- Procedures to segregate different types of fuel and fuels from different sources

- Detailed procedures for compatibility testing and segregating fuels from different sources until compatibility can be confirmed

- Procedures to changeover from one type of fuel to another or a fuel oil that is known to be incompatible with another fuel oil

- Plans to address any mechanical constraints with respect to handling specific fuels, including ensuring that minimum/maximum characteristics of fuel oil as identified in ISO 8217 can be safely handled on board the ship

- Procedures to verify machinery performance on fuel oil with characteristics with which the ship does not have prior experience.

Click here for the relevant IMO guidance MEPC.1/ Circ.878 (Guidance on the development of a ship implementation plan for the consistent implementation of the 0.50% sulfur limit under MARPOL Annex VI).

Do not hesitate to contact us for any clarifications you may need on the above.

NL 204/19|Panama Maritime Administration - Mandatory Annual SSAS Test

Company Security Officers (CSO) of companies operating Panamanian flagged vessels are reminded that PMA, as from January 1st, 2018 requires to carry out a mandatory annual SSAS TEST through the online platform in use from PMA, according to MMC-133 and the new MMC-371.

In case of vessel changes name, it will be necessary to schedule a new SSAS TEST, through the platform, in order to verify that the new name was programmed properly.

The Administration urges Companies, Company Security Officers (CSO), Ship Security Officers (SSO) and the Recognized Security Organization (RSOs) of Panamanian flagged vessels to verify and comply with this Resolution

and the MMC 133.

For ships to enter the Panamanian registry as of January 1st, 2018, they must schedule the first SSAS TEST through the use of the new platform, which must be verified by their RSO during the initial verification and from that date onwards, every 12 months. In those cases, it must also be ensured that the Company Security Officer designated by the Company Operator already has the Declaration of Company Security Officer duly endorsed by Panama Maritime Authority (as per MMC-206) in order to schedule the first SSAS TEST according to MMC 133.

PHRS, since January 2018, requires the verification of evidence of SSAS annual test records during Initial verifications onboard ships for which PHRS is the RSO, in accordance to the requirements set by PMA.

For further information on the actions to be taken by the CSOs, Ship-managers/owners/operators can also refer to PHRS Newsletter NL 192 of 2017 [ NL 192/17 | New Panama Flag Regulation for the use of the Ship Security Alert System (SSAS) ] and the attached MMC-133 and MMC-371.

Do not hesitate to contact us for any clarifications you may need on the above.

January 15th, 2019 - PHRS Head Office

"Επιθεωρήσεις Σκαφών Αναψυχής : Το παρόν και το μέλλον" - Ενημερωτική Εκδήλωση στο Ίδρυμα Ευγενίδου

Στις 20 Νοεμβρίου ο Οργανισμός διοργάνωσε την ενημερωτική εκδήλωση / ανοιχτή συζήτηση "Επιθεωρήσεις σκαφών αναψυχής: το παρόν και το μέλλον" στην αίθουσα εκδηλώσεων του Ιδρύματος Ευγενίδου. Στην εκδήλωση, πάνελ ομιλητών αποτελούμενο από στελέχη του Οργανισμού συνομίλησε με το κοινό για θέματα σχετικά με την προετοιμασία μιας επιθεώρησης, τα απαραίτητα δικαιολογητικά που πρέπει να υποβληθούν, την διενέργεια της επιθεώρησης καθώς και για καίρια ζητήματα που απασχολούν όλους τους εμπλεκόμενους στον χώρο των σκαφών αναψυχής. Ιδιαίτερη αναφορά έγινε και στο νέο θεσμικό πλαίσιο επιθεωρήσεων σκαφών σε συνδυασμό με τις αναβαθμισμένες υπηρεσίες που παρέχει ο Οργανισμός στον τομέα της πιστοποίησης.

Την ημερίδα τίμησαν με την παρουσία τους υφιστάμενοι πελάτες του Οργανισμού, συνεργάτες, εκπρόσωποι φορέων (ΣΙΤΕΣΑΠ, ΕΠΕΣΤ, ΠΕΝΕΤΗΣ κ.α), ναυτικοί πράκτορες, πλοιοκτήτες και επαγγελματίες που δραστηριοπούνται στην εκμετάλλευση τουριστικών σκαφών.

Όλο το ενημερωτικό υλικό της παρουσίασης είναι διαθέσιμο, κατόπιν αιτήματος, στο email jenny.arvanitaki@phrs.gr .

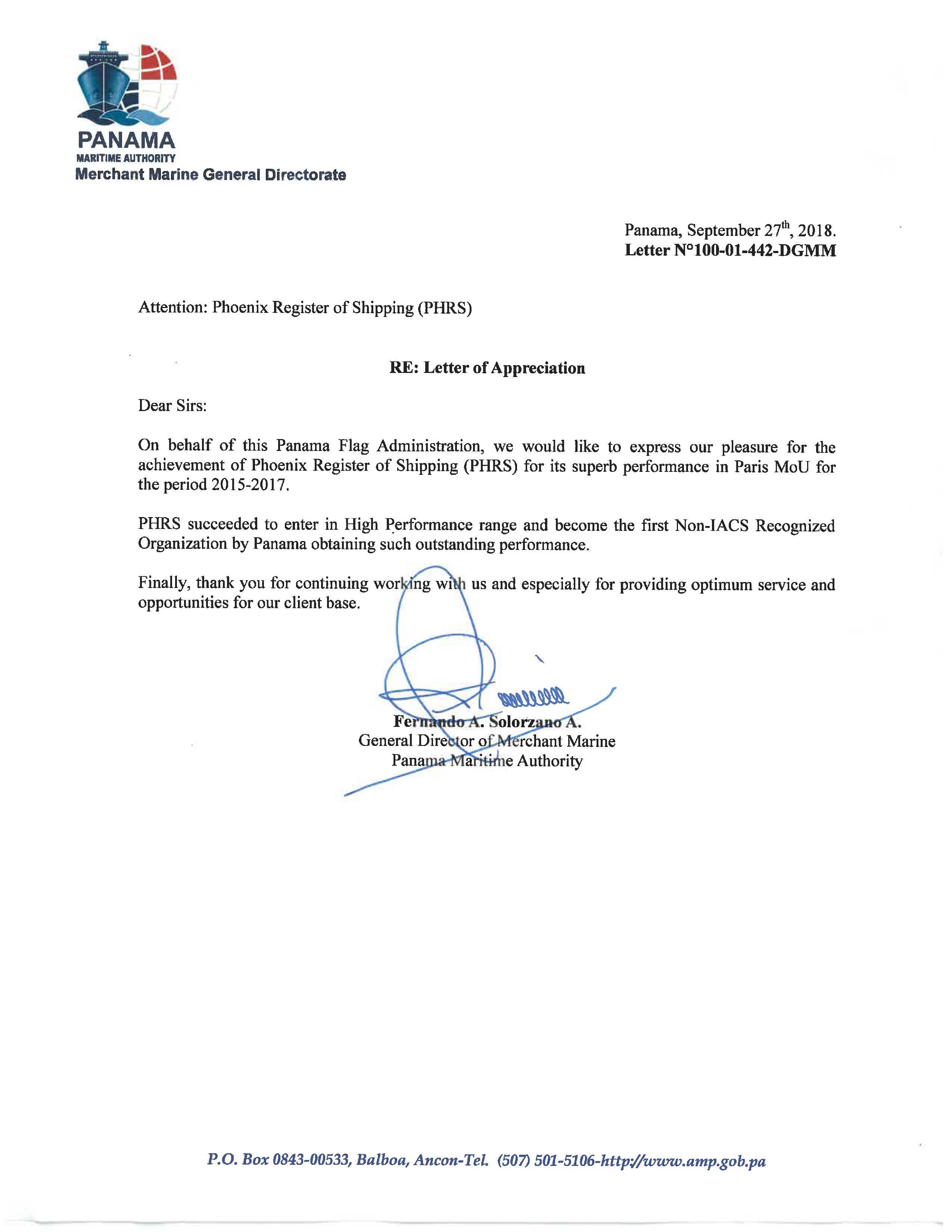

Appreciation Letter from Panama Flag Administration regarding PHRS's performance in Paris MoU

We are pleased to share the appreciation letter we received from Panama Flag Administration regarding PHRS’s outstanding performance in Paris MoU evaluation list for the period 2015-2017.

The fact that Phoenix Register of Shipping is the first Greek Classification Society to enter the High Performance Rank, did not go unnoticed by Panama Flag Administration, the world’s largest Flag Administrations with a total fleet of over 8.000 vessels.

Such recognition keeps us inspired to continue our ever- ending work regarding the safety of human life at sea and the protection of the marine environment.